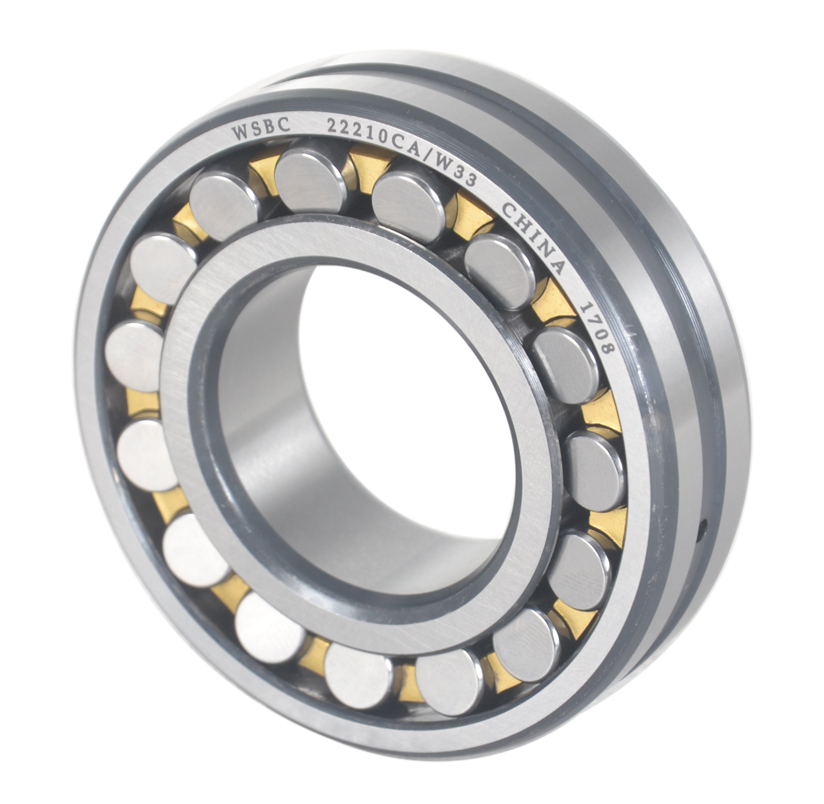

High Quality In Wholesale Spherical Roller Bearing

Product Name:High Quality In Wholesale Spherical Roller Bearing

Model Number:22210c,22222.22211ca

Size:50*90*23mm

Number of Row:double row

Material:Chrome Steel Gcr15

Delivery Time:1-3 days for Samples or in Stock2) 10-15 Days for Ordering

cylindrical roller bearings are bearings in which cylinders are used as the rolling elements as opposed to balls in ball bearings.As such, the rollers have a greater (linear) contact area with the outer ring and are distribute loads across a broader surface.Subsequently, they have a relatively high radial load capacity and are suitable for high speeds. Double-row cylindrical roller bearings have high radial rigidity and are used primarily for precision machine tools.

Maintenance method

1、When the bearings run to a certain period (or maintenance period), all the bearings will be removed.

2、Wash the bearings with diesel oil or paraffin, if there are technical conditions, it is best to open the seal cover to clean.

3、After cleaning, dry the cleaning oil and check the appearance for any damage.

4, with a 150mm or so, the diameter of the angular contact ball bearing inner diameter of the same wooden rod (preferably hollow tube), one end fixed a bearing.

5、While turning the bearing quickly by hand, put the other end of the stick (wooden tube) against the ear or audio amplifier microphone to listen to the bearing rotation noise.

6、After fixing the bearing, pivot the stick horizontally to check if the bearing is worn and loose.

7, loose serious, excessive rotating noise, there are serious defects in the FAG bearing should be eliminated, with the same model instead.

8、Take a barrel to melt the appropriate amount of grease (high quality yellow dry oil) with a civilian fire (not overheated), the tested bearing into the barrel soaked to no bubble overflow. Remove the bearing before the grease cools down, with a small amount of residual grease. Remove the angular contact ball bearing after the grease has cooled, the amount of residual grease is high. Determine the amount of grease residue as needed.

9、Wipe the grease outside the bearing with a soft cloth or toilet paper and assemble the FAG bearing to the pulley in its original state, the maintenance work is finished.