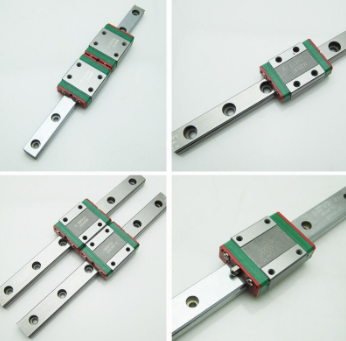

Mechanical Guide Rail

Mechanical guide rails also offer versatility in their applications. They can be used as simple guide rails or combined with other components to create more complex assemblies. For example, they can be used in combination with roller conveyors or chains to provide even more precise movement control. This versatility makes mechanical guide rails an ideal choice for a wide range of industries and applications.

Mechanical guide rail

Overall, mechanical guide rails are an essential component in many industrial and manufacturing environments. They offer durability, precision, and versatility, making them an ideal choice for many applications. Whether used in conveyor systems, automated machinery, or other production environments, guide rails play a critical role in ensuring that operations run smoothly and efficiently. As technology continues to evolve, we can expect to see even more innovative uses for mechanical guide rails in the years to come.

One of the key benefits of mechanical guide rails is their durability. Unlike other types of guiding systems, such as belts or rollers, guide rails are highly resistant to wear and tear. They can withstand heavy loads, regular use, and exposure to harsh environments without crumpling or breaking down. This means that mechanical guide rails are ideal for use in high-volume production environments where uptime and reliability are essential.