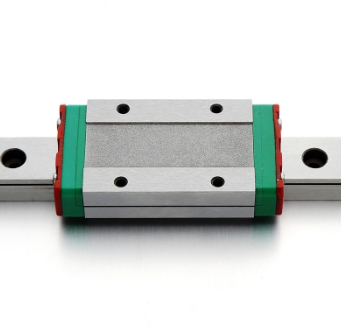

Carriage And Rail

Condition:New

Warranty:1.5 years

Applicable Industries:Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Retail, Printing Shops, Energy & Mining, Mechanical Processing Manufacturing, Automation

Marketing Type:New Product 2023

Warranty of core components:1.5 years

Core Components:Rail and Block

Material:Bearing steel,Stainless steel

Length:100-4000mm(Custmized )

After Warranty Service:Online support, Spare parts

The mechanical guide rail itself is typically a long, slender piece of metal or alloy that is mounted to a stationary surface. The moving component, which is typically a slider or carriage, is attached to the guide rail via bearings or bushings. This setup allows the slider to glide smoothly along the rail, guided by its precise and linear geometry.

One of the key benefits of using mechanical guide rails is their ability to withstand high loads and forces. They are designed to support a wide range of loads, from small light-weight components to heavy-duty machinery. This makes them an ideal choice for applications where there is a need for high load capacity and stiffness.

Mounting forms

Angular contact ball bearing fast and easy automatic selection book can provide selection, angular contact ball bearing mounting forms, there are back-to-back, face-to-face and tandem arrangement of three. Back to back (two bearings of the wide end face relative) installation, bearing contact angle line along the direction of the rotary axis diffusion, can increase its radial and axial support angle rigidity, resistance to deformation capacity of the largest; face to face (two bearings of the narrow end face relative) installation, bearing contact angle line towards the rotary axis direction convergence, its support angle rigidity is smaller. As the inner ring of the bearing extends out of the outer ring, when the outer ring of the two bearings are pressed together, the original clearance of the outer ring is eliminated, which can increase the preload of the bearing; Tandem arrangement (the wide end face of the two bearings in one direction) when installed, the contact angle line of the bearing in the same direction and parallel, can make the two bearings share the same direction of the working load. However, when using this mounting form, in order to ensure the axial stability of the installation, two pairs of bearings in tandem arrangement must be installed at the opposite ends of the shaft.