Row Cylindrical Roller Bearings

Row Cylindrical roller bearings

Cylindrical roller bearings (CRBs) have a easy shape with their cylindrical rollers in linear contact with the raceways. They provide excessive load potential beneath chiefly radial loads. Low friction between the rollers and ring ribs makes these bearings appropriate for excessive velocity rotation.

Excellent sealing

High load capacity

Easy grease replenishment

Corrosion-resistant

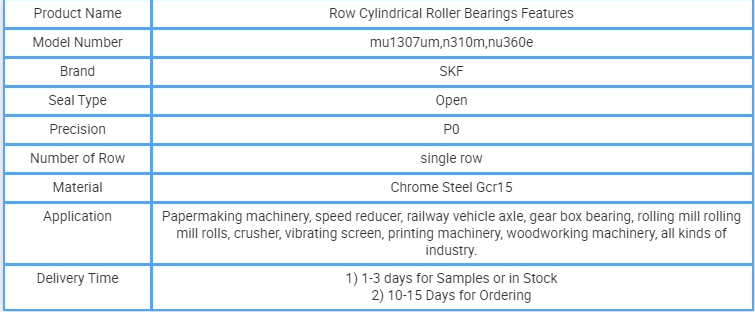

Row Cylindrical Roller Bearings Features

High load carrying capacity

The cage bars are displaced relative to the roller pitch diameter to allow the rollers to be positioned nearer to every other, growing room for extra rollers

High stiffness

The extended range of rollers will increase radial stiffness.

High velocity capability

The cage designs are appropriate for excessive speeds, speedy accelerations and top loads.

Long provider life

The black oxide coating of rings and rollers (designation suffix L4B) contributes to prolonged carrier lifestyles by way of improving:

Smearing harm resistance

Running-in residences and decreasing friction

Performance beneath terrible lubrication conditions

Chemical resistance (from agressive oil additives)

Corrosion resistance

Row Cylindrical Roller Bearings Application

have the immoderate load carrying functionality of full complement bearings and the immoderate speed performance of bearings with cage. They are designed for functions such as industrial gearboxes, wind turbine gearboxes and mining equipment.

Row Cylindrical Roller Bearings details

For the specific content of cylindrical roller bearings, please refer to the following table